Filling and closing machine for plastic bottles

Machine type FVK 50400

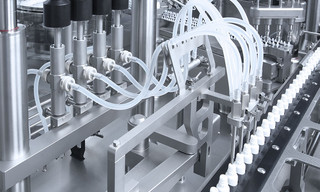

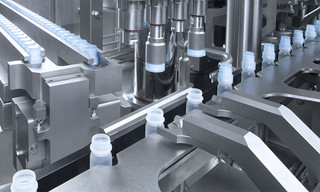

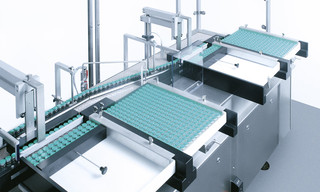

The FVK is an intermittent motion machine for fully automatic sorting, filling and closing of plastic bottles. The containers are conveyed through the work area in an intermittent motion by a walking beam system which handles the containers very gently. The dosing station is designed for processing liquid products using four rotary piston pumps. Alternatively, or additionally, the machine can be equipped with peristaltic pumps. The closing stations can process droppers, screw caps, snap-on caps and multi-dose dispensers.

HIGHLIGHTS

- 100 % IPC at full output

- Product-carrying parts are sterilizable / autoclavable

- Pharmaceutical design

- Optimal laminar air flow

| Type of machine | Output | Processing range |

|---|---|---|

| FVK50400 |

|

|

Easy and centralized operation

Low-particle closure feed

Gentle container transport

Wide range of inspection options

- Compatible with a range of dosing systems

- In-Process Control (IPC)

- Reject discharge

- Closure feed from supply system

- Service Portal Vision System (suitable for use in clean rooms)

- Compatible with a range of checking and alarm devices and counters

- Software upgrades

- Qualification (IQ/OQ)